Operating trucks in Western Australia heat exposes engines, cooling systems, drivetrains, and auxiliary components to sustained thermal stress that directly affects reliability, performance limits, and asset lifespan. In WA, extreme ambient temperatures combine with long distances and heavy loads, making heat management an operational constraint, not a seasonal inconvenience. Understanding how heat impacts truck systems is essential to preventing derating, downtime, and premature component failure.

Why Heat Is a Primary Operating Constraint in WA

Western Australia’s operating environment subjects trucks to:

- prolonged ambient temperatures well above design baselines,

- extended run times between service and refuelling points,

- sustained load cycles with limited recovery periods.

Unlike short-haul or urban operations, WA heat exposure is continuous, which compounds thermal load across multiple systems simultaneously.

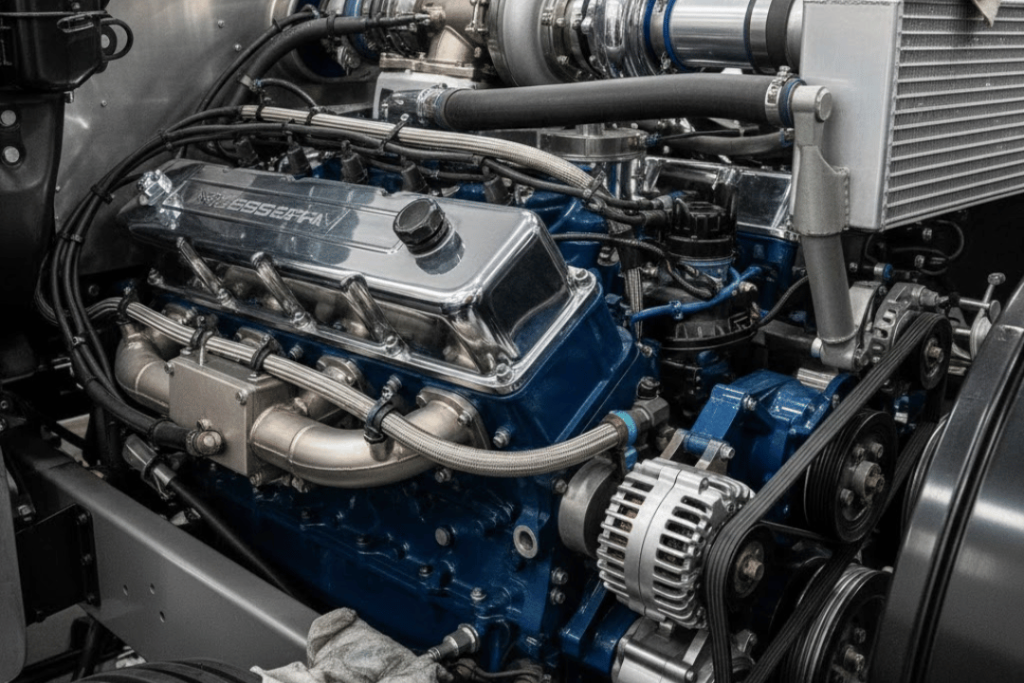

How Heat Affects Truck Engines

Combustion Efficiency and Thermal Load

High ambient temperatures reduce air density, which affects combustion efficiency and increases exhaust gas temperatures. Engines working under load in hot conditions experience:

- higher internal temperatures,

- increased stress on pistons, valves, and turbochargers,

- reduced tolerance for marginal cooling performance.

Modern engines compensate through electronic controls, but this often results in power derating to protect components.

Lubrication Breakdown

Heat accelerates oil degradation. In WA conditions:

- oil viscosity breaks down faster,

- oxidation rates increase,

- lubrication margins narrow under load.

This shortens effective service intervals and increases wear if not managed correctly

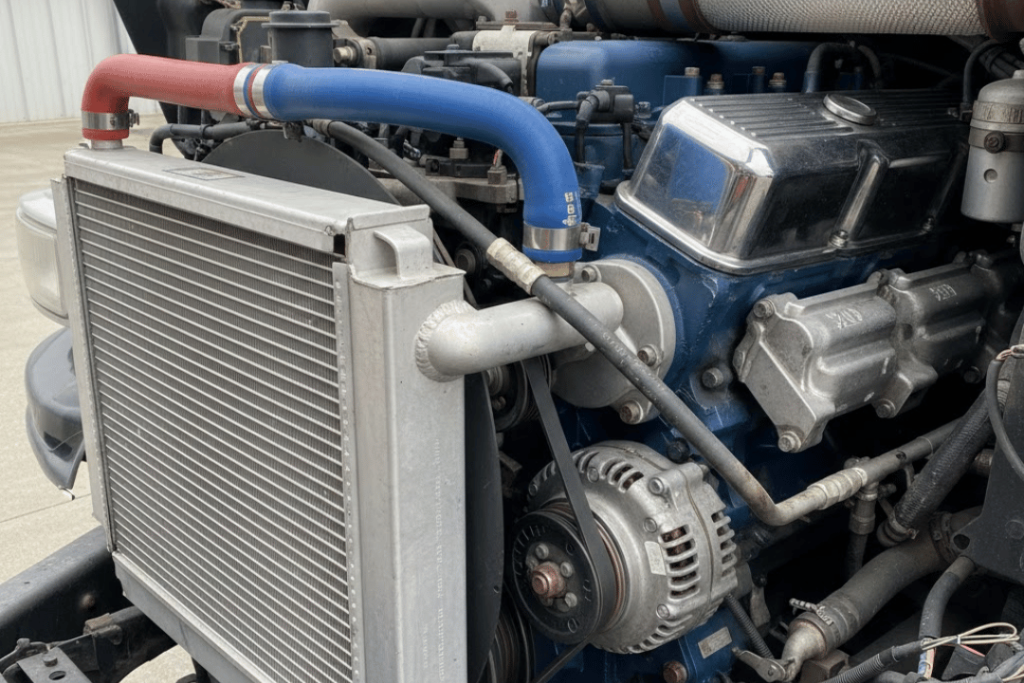

Cooling Systems Under Extreme Heat

Radiator and Airflow Capacity

Cooling systems are designed around temperature differentials. As ambient temperatures rise, that differential shrinks, reducing heat rejection capacity. Trucks operating in WA require:

- higher-capacity radiators,

- effective fan and shroud design,

- unobstructed airflow across cooling cores.

Any restriction on dust, debris, or poor configuration has a magnified impact in hot conditions.

Cooling System Failure Risk

Under heat stress, weak points emerge quickly:

- hoses harden and fail,

- seals degrade,

- coolant loses efficiency.

Cooling system failures in remote WA locations can result in extended downtime and recovery costs, not just repairs.

Impact of Heat on Drivetrains and Transmissions

Transmission Temperature Management

Automatic and automated manual transmissions generate heat under load. In hot operating conditions:

- transmission fluid temperatures rise faster,

- cooling capacity is reduced,

- thermal protection systems may limit performance.

Incorrect transmission cooling specification is a common cause of reliability issues in WA fleets.

Differential and Axle Stress

Sustained heat affects:

- gear oil performance,

- bearing life,

- seal integrity.

Heavy loads over long distances compound this stress, particularly in mining and regional haulage applications.

Electrical and Electronic Systems in High Heat

Modern trucks rely on sensors and control modules that are sensitive to temperature extremes. Prolonged heat exposure can lead to:

- sensor drift,

- connector degradation,

- intermittent electronic faults.

These issues are difficult to diagnose and often mistaken for isolated failures rather than systemic heat stress.

Operational Consequences of Ignoring Heat Effects

Reduced Reliability and Increased Downtime

Heat-related stress manifests as:

- unexpected derating,

- warning alarms,

- limp modes,

- component failures under load.

These events rarely occur near depots or service centres in WA.

Accelerated Asset Fatigue

Even without immediate failures, sustained heat shortens the usable life of:

- engines,

- transmissions,

- cooling systems,

- electrical components.

This increases the total cost of ownership long before end-of-life is reached.

Why Generic Operating Assumptions Fail in WA

Trucks configured for cooler or shorter-duty environments often struggle in WA because:

- cooling margins are insufficient,

- service intervals are unrealistic,

- component protection thresholds are exceeded regularly.

WA heat requires intentional specification and operational planning, not adaptation after failure.

How Operators Should Evaluate Heat Suitability

Heat suitability should be assessed by examining:

- cooling system capacity under load,

- thermal limits of drivetrains,

- oil and fluid performance ranges,

- expected duty cycle duration in peak temperatures,

- support and parts availability in WA.

This evaluation must occur before deployment, not after problems emerge.

WA Heat-Ready Truck Advice from Western Truck Sales

Operating trucks in Western Australia heat demands more than choosing a powerful vehicle. It requires ensuring that cooling capacity, drivetrain specification, and thermal protection match real operating conditions, not ideal ones.

Western Truck Sales works with WA operators to assess how extreme heat affects truck performance, reliability, and long-term operating costs. Our focus is on matching vehicles to actual duty cycles and environmental stress, helping fleets avoid heat-related failures and premature asset fatigue.

If your trucks operate in sustained heat, long-haul, or heavy-load environments, getting WA-specific guidance before purchase or fleet expansion can significantly reduce risk.

Contact Western Truck Sales to discuss truck options and specifications suited to extreme heat operation in Western Australia.